mellow

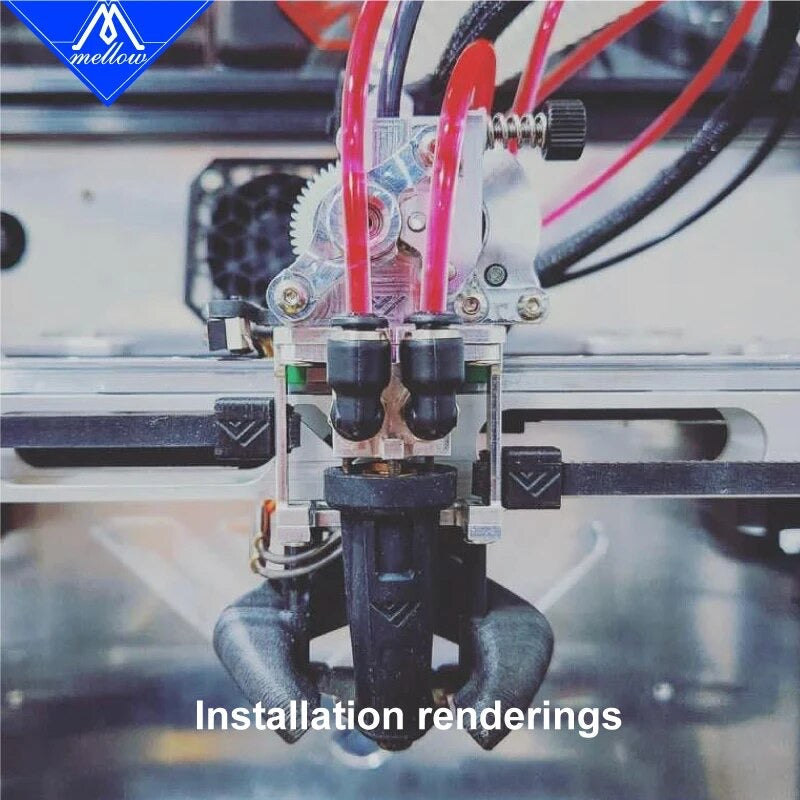

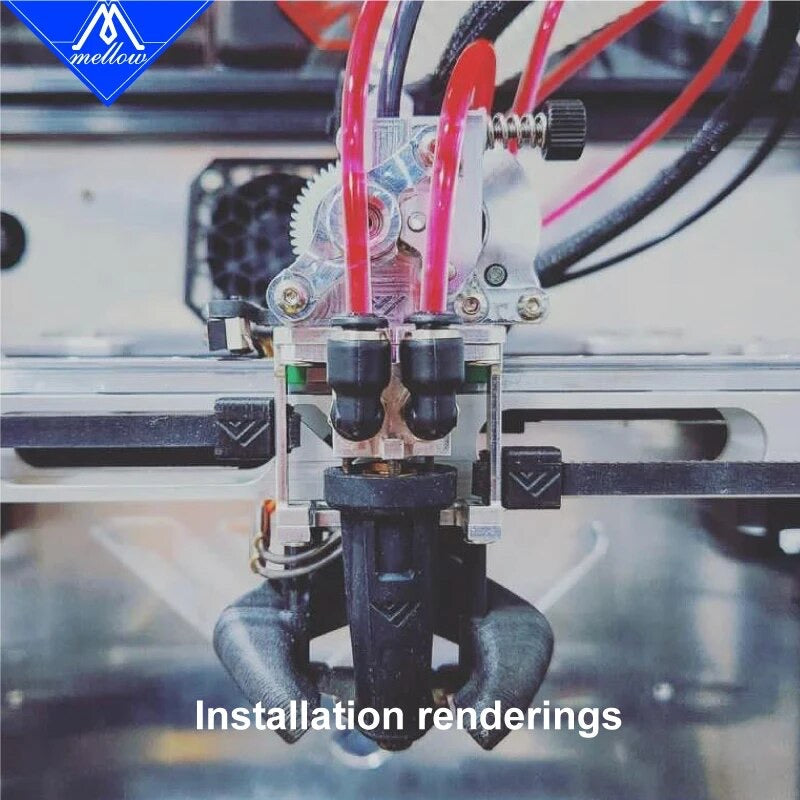

Mellow CNC All Metal Vz-Hextrudort-Low/WC Extruder One Shaft Twirl Gear For VzBoT 330 VZ235 HevORT 3D Printer 1st gen

Mellow CNC All Metal Vz-Hextrudort-Low/WC Extruder One Shaft Twirl Gear For VzBoT 330 VZ235 HevORT 3D Printer 1st gen

Regular price

$54.99 USD

Regular price

Sale price

$54.99 USD

Unit price

per

Couldn't load pickup availability

-

The gear of this extruder is made of hardened steel with a strength of 55, which can withstand long printing periods without damaging the gear. To improve the concentricity of extrusion and the stability of filament passage, we adopted an integrated shaft gear design based on the suggestion of the VzBoT team, and produced reduction gears with high-precision CNC machining to reduce the runout in gear transmission.

-

Compared to injection gears, this gear has smaller tolerance and deformation, which can significantly improve the precision and stability of the extruder. For maximum weight reduction, we also hollowed out the reduction gear while maintaining its strength.

-

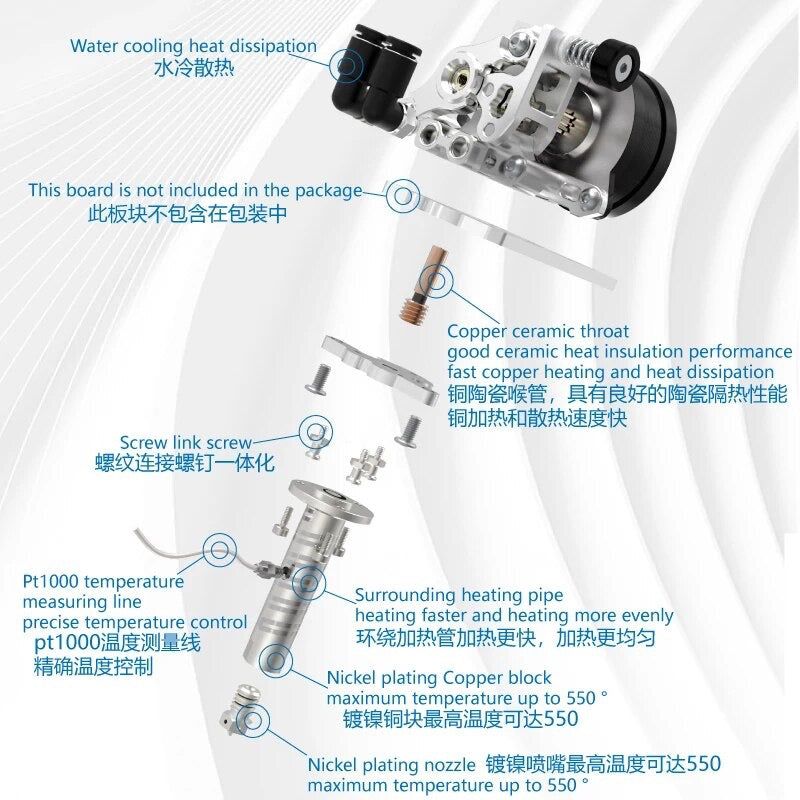

The shell design of the extruder is from the VzBoT team and is made of high-precision CNC machined 6061 aluminum alloy. The material not only has the strength of metal, but also has ultra-light weight. The strength and precision of metal shells are higher than those of plastic shells, which can effectively protect internal mechanical components and extend the service life of the machine. The metal material has excellent thermal conductivity, which can conduct the heat of the motor, ensure the stability of the printing process, and is also the process of motor heat dissipation, which ensures the service life of the motor.

-

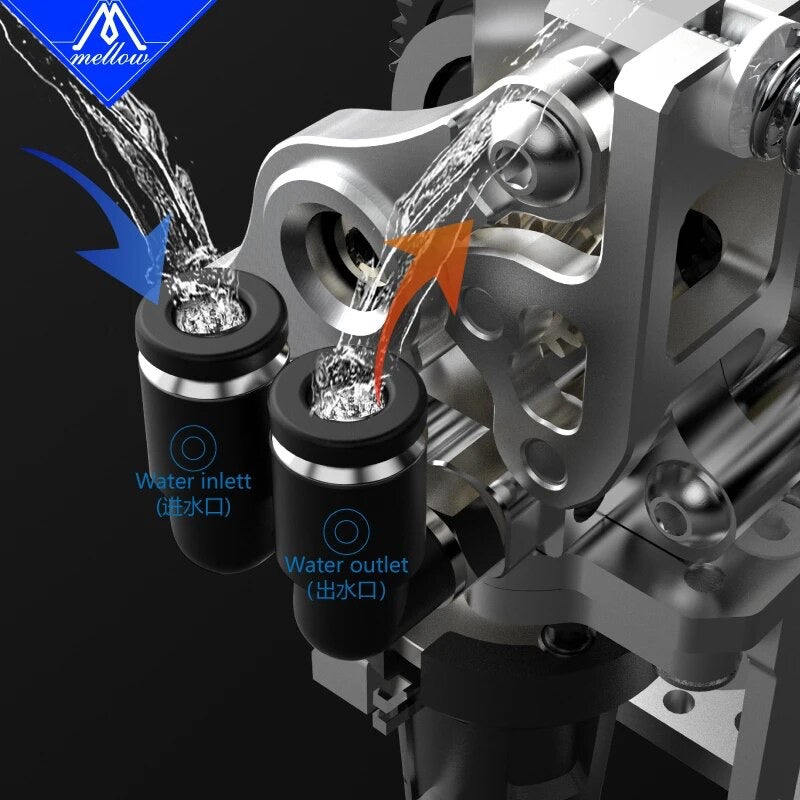

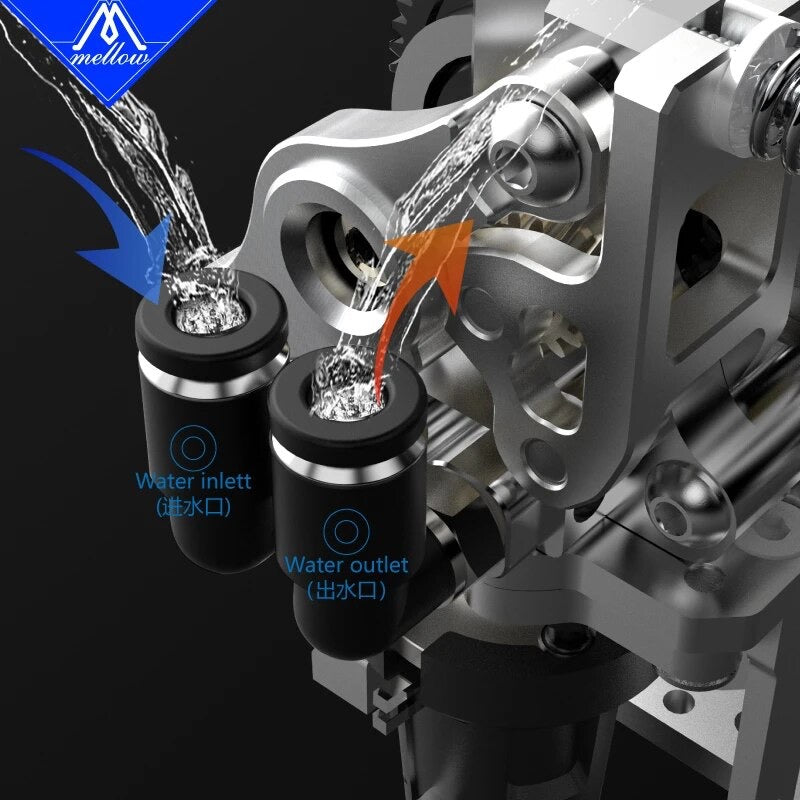

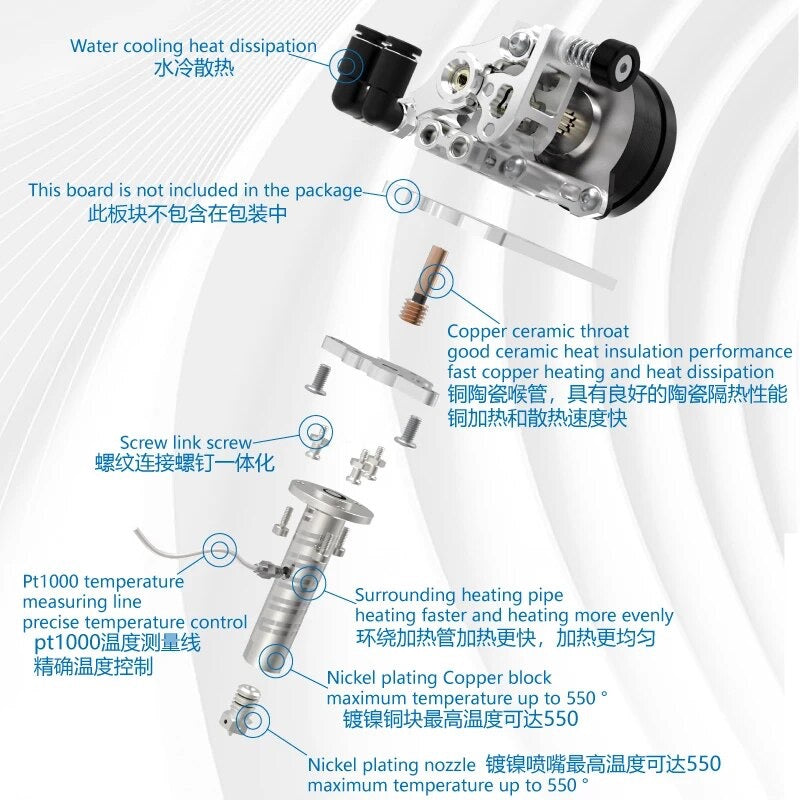

The water cooling structure can cool the hot end and the motor at the same time, improving the printing performance of the hot end and ensuring stable operation of the motor under high temperature conditions, thus improving the stability and reliability of the machine.

-

We also adopted a new twirl gear design to increase friction and reduce gnawing, further improving the performance of the extruder. The reduction ratio of the extruder is 1:6.25 or 1:5, and the pulse is set to 895-905 when using an 8-tooth motor and 685-695 when using a 10-tooth motor. The drive uses 2209, and the recommended motor current is 0.6A-1A, which can effectively control the operation and printing process of the machine.

-

In summary, this extruder has excellent performance and stability, can meet various extrusion printing needs, and has a long service life. It is a reliable and high-quality extruder.